Indispensable for perfect cast iron and steel products

RICHARD ANTON KG carburising agents are used for the efficient and accurate adjustment of the desired carbon content in the molten iron.

The various types differ in the type of raw material, grain size and grain shape, each tailored to the individual requirements, thus guaranteeing optimum dissolution in the melt.

The raw materials used include calcined petroleum coke, high-quality synthetic graphites and anthracite grades.

The selection of the appropriate carburising agent depends on the cast iron alloy to be produced.

For cast iron with nodular graphite (EN-GJS) or vermicular graphite (EN-GJV), we recommend graphite materials with low sulphur and nitrogen content.

For the production of cast iron with flake graphite (EN-GJL) or cast steel (EN-GS), on the other hand, materials with medium and high sulphur and nitrogen content based on petroleum coke or anthracite are suitable.

Selection of the carburising agent

The following are important in order to ensure optimum carbon recovery in the melt:

- The right type of raw material

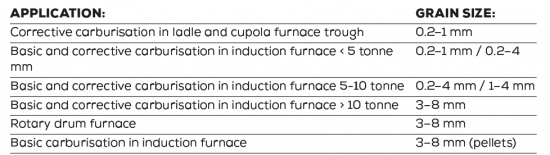

- The right grain size

- The type of melting unit

- The timing of addition to the melt